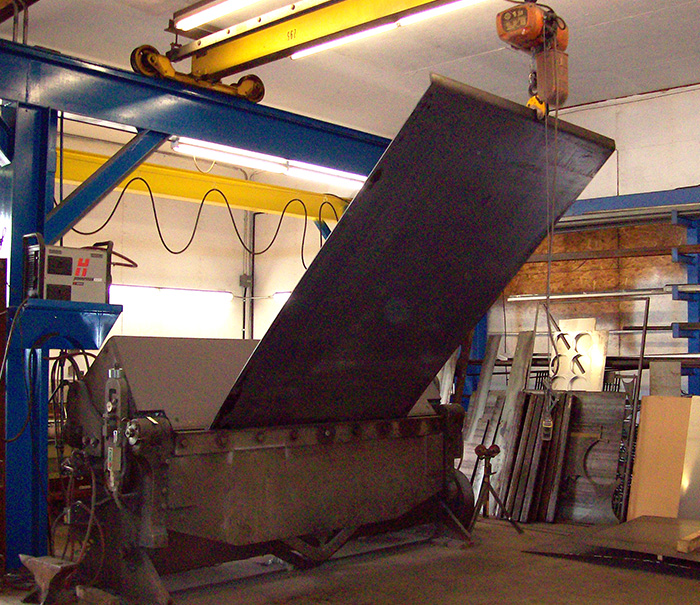

6000W Laser Cutting Machine

The company's laser cutting machine operating table is 2500mm * 6000mm, the finished product has a large single block area, and there are few welding points in the later stage. Laser cutting processing replaces traditional mechanical knives with invisible beams. It has high precision, fast cutting, is not limited to cutting pattern limitation, saves materials by automatic typesetting, smooth cuts, low processing cost, etc., and will gradually improve or replace The traditional Jin Li cutting process equipment, the mechanical part of the laser cutter head has no contact with the workpiece, and does not cause scratch on the surface of the workpiece during the work: the laser cutting speed is fast, the slit is smooth and flat, generally no subsequent processing is required: the cutting heat affected zone is small, The deformation of the plate is small, the slit is narrow (0.1mm~0.3mm); the cut has no mechanical stress, no shear burr: high processing precision, good repeatability, no damage to the material surface: NC programming, can process any plan, can be on the web Large plate cutting without the need to open the mold, saving time and money