Rust is a component which most people want to avoid. However, when people

purchase weathering steel this is the component which is sought after. In weathering steel, rust extends the lifecycle of a

weathering steel structure, it also helps to reduce the time and expense associated with maintaining the structure.

Weathering steel was created with small amounts of copper, phosphorus, chromium, nickel and silicon put into the steel on purpose, to allow the steel sheets form a rust layer when left open to the weather, eliminating the need for paint.

Rust assists in protecting the weathering steel from additional corrosion. The steel creates a protective barrier of rust, which initially looks unremarkable, in order to protect the steel when open to further moisture and oxygen.

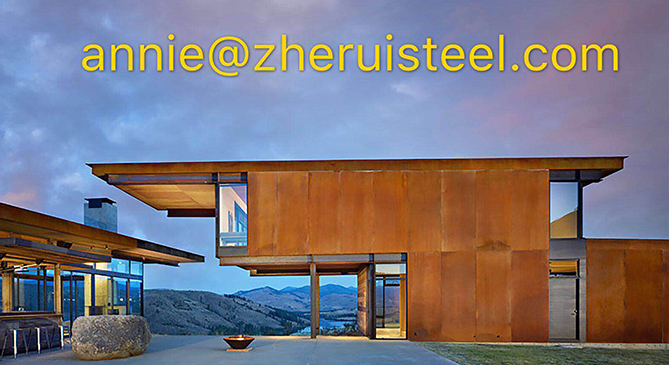

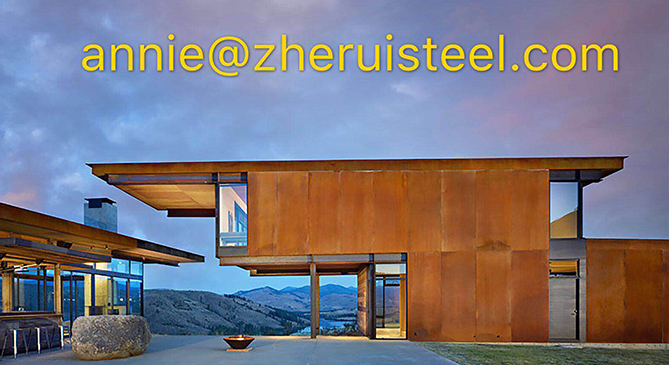

Once the rust has formed on the weathering steel, it has an attractive appearance. The steel takes a reddish, orange colour of rust. As the steel is exposed to the elements further, the colour develops.

Weathering steel is a good option to use in buildings and architecture due it its low maintenance. It is also a high strength steel, which means it can be used in the building of bridges for example. Weathering steel is ideal for use in building bridges due to it’s high strength and low maintenance. Bridges would require regular inspection and cleaning but wouldn’t require painting. Not having to paint this type of steel is of benefit to builders as they can avoid the health issues regarding volatile organic compounds which are a health concern in certain paints.

Rust is a component which most people want to avoid. However, when people purchase weathering steel this is the component which is sought after. In weathering steel, rust extends the lifecycle of a weathering steel structure, it also helps to reduce the time and expense associated with maintaining the structure.

Rust is a component which most people want to avoid. However, when people purchase weathering steel this is the component which is sought after. In weathering steel, rust extends the lifecycle of a weathering steel structure, it also helps to reduce the time and expense associated with maintaining the structure.