The terminal structure of Beijing Daxing International Airport has a complex structure and a large space span, covering an area equivalent to 63 Tiananmen Square. The new airport terminal complex is constructed by Beijing Urban Construction, Beijing Construction Engineering, and China Construction Eighth Bureau, of which Beijing Urban Construction is responsible for a construction area of over 600,000 square meters, the most core and the most complicated. The central area has the largest single concrete floor in the country, and the "bird's nest" can be placed on it, which is equivalent to 25 standard football fields. This information was already clear before visiting the new airport. But when really walking into this steel forest, the reporter of China Metallurgical News was still shocked by the spectacular sight in front of him.

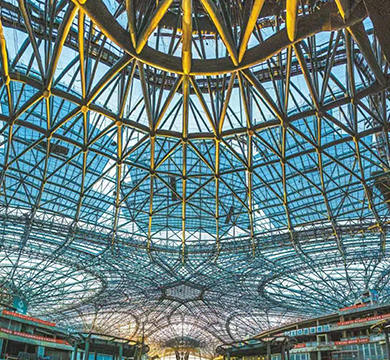

The new airport terminal looks like a rainbow, looking from a distance, like a golden phoenix fluttering. The interior design is magnificent and the color tone is mainly white. The huge dome is welded by 63400 steel structures. The amount of steel is equivalent to half a "bird's nest". The large-span, irregularly-shaped overweight dome is only supported by 8 C-shaped columns, just like 8 giant white Ganoderma ...

Li Jianhua told the reporter of "China Metallurgical News": "The total steel consumption of the new airport terminal complex is 450,000 tons, the main body is a cast-in-situ reinforced concrete frame structure, part of which is a steel concrete structure, and the roof and its support are steel structures. The total weight of the steel structure is about 130,000 tons. The steel structure construction involves GS20MnQT,

Q345 (Q345B, Q345C, Q345GJC, Q345qD) series, Q390GJC, Q460GJC and other steel varieties. "

Li Jianhua pointed out that the construction of the new airport requires requirements for the impact toughness and weldability of the steel. The impact toughness requires that the ratio of the yield strength of the steel to the measured value of the tensile strength should not be greater than 0.85. The steel should have a significant yield step and elongation. The rate should not be less than 20%; the weldability requires that the carbon equivalent (CEV) of different types of steel ≤0.40 ~ 0.44, and the crack sensitivity index Pcm≤0.20% ~ 0.29%; the delivery status of Q460GJC and Q390GJC is TMCP (Thermo-mechanical control process ).

On the second floor of the new airport terminal, there are 8 C-shaped columns resembling Ganoderma lucidum, which together with 12 groups of supporting columns, curtain wall columns and other structures support the airport core area covering an area of 180,000 square meters, thus realizing the roof structure of the terminal. Integration with load-bearing structures. According to reports, the C-shaped column bears a large load, so it has high material requirements. Q460GJC and Q390GJC low-alloy high-strength structural steel are mainly used. The steel is required to have good weldability and a low crack sensitivity index. The round steel pipe used for the construction of the 180,000 square meter roof grid is a hot-rolled seamless steel pipe.

Daxing International Airport has attracted worldwide attention. Behind it, there are not only Chinese engineering builders working hard and hard at night and hard, but also the determination of Chinese iron and steel people to shoulder the burden and overcome difficulties. With a large number of high-quality and high-end steel products, they have propped up the wings of the new airport and provided a "China solution" to solve world problems. Iron Phoenix, Iron is the Wing!