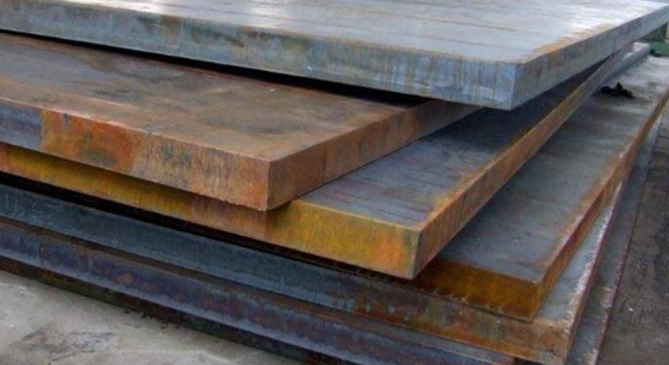

The emergence of any new thing has its rationality and legitimacy. At the same time, it can not be separated from the dependence on the characteristics of the current era, as is the emergence of steel plate cutting. For example, a place that requires the use of steel plates, but there are special requirements for the shape of the steel plate. At this time, it is naturally necessary to use steel plate cutting.

It should be noted that in the process of steel plate processing, some equipment has relatively high requirements for the thickness of the steel plate. For example, in the shipyard, in order to improve the impact resistance of the ship, it is necessary to select extra thick steel plate for installation and application. Steel plates are thicker than ordinary steel plates, so what skills do you need to master when cutting extra thick steel plates?

When cutting extra-thick steel plates, the cutting speed should not be too fast. In order to speed up the processing of many thick steel plates, many details are often ignored. In this way, it is easy to produce waste parts and some plates will crack. Therefore, when cutting extra thick steel plates, you must pay attention to the speed It should not be too fast, and it should be dominated by low-speed processing, which can effectively improve work efficiency.

When cutting extra-thick steel plates, it is necessary to preheat in advance, and some plates are prone to cracks after entering the cutting process, and sometimes it is caused by the temperature being too low, so it is necessary to advance in this case. Pre-heat treatment is carried out, so that the temperature of the plate will gradually increase, and then it can be cut by a flame gun. The probability of cracks in the cut material is very low, and the quality of the plate is also guaranteed.

AHL STEEL has years of experience in steel plate sales and cutting. If you need it, please contact our online customer service. We believe that with your suggestions and help, we will do better.