Do you know what rolled steel is? Steel rolling is a type of metal pressure processing. The steel ingot is changed between the whirlwind rolls, and the pressure processing of the billet shape is called steel rolling.

The purpose of steel rolling is the same as other pressure processing, on the one hand, in order to obtain the required shape. For example: steel plate, strip steel and various types of steel. On the other hand, in order to improve the internal quality of steel, our common automobile steel plates, bridge steel plates, boiler steel plates, etc., including train wheels, are processed by steel rolling process.

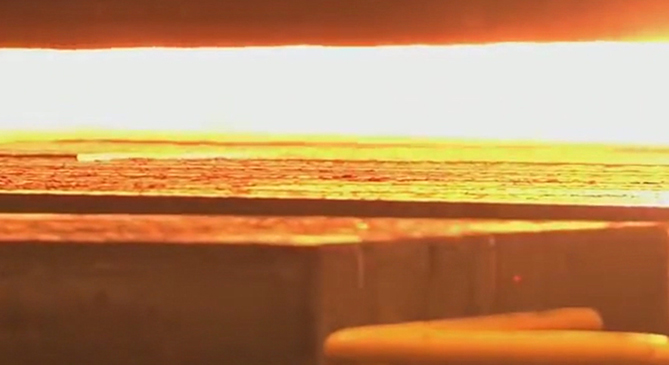

At the same time, steel rolling is divided into hot rolling and cold rolling. The hot-rolled steel sheet is rolled into a steel with different cross-sectional shapes that can be used by a steel machine. Cold-rolled steel plates are usually hot-rolled blanks, which are pressed by rolling mills to become thinner and smoother plates under normal temperature conditions without heating.

Hot rolled steel is easy to roll and has high rolling efficiency, but the steel is oxidized under hot rolling conditions and the surface of the product is dark gray. Cold rolled steel requires high rolling mill power and low rolling efficiency, and intermediate annealing is required to eliminate work hardening during the rolling process, so the cost is also high, but the cold rolled steel has a bright surface and good quality, which can be directly used for processing For finished products, the cold-rolled steel sheet is widely used.

AHL STEEL has always been committed to steel plate sales and steel plate cutting and processing, strictly controlling quality, and its products have been well received by customers after being put on the market. If you have a demand for steel plates, you are welcome to call us. We believe that with your suggestions and help, we will do better.